Fiberglass mesh cloth: the "invisible guardian" of the European construction market

Time:

2025-05-13

In Europe, fiberglass mesh cloth has long become an indispensable star material in the construction field. From the quaint cottages at the foot of the Alps to the modern skyscrapers in the Nordic cities, it silently protects the quality of buildings as an "invisible guardian". Today, let us explore the wide application of fiberglass mesh cloth in the European market.

1. Advantages of being widely used in construction

(I) Excellent crack resistance

Europe has a diverse climate, from the severe cold in Northern Europe to the high temperature in Southern Europe, and the walls of buildings are prone to thermal expansion and contraction due to temperature changes. Fiberglass mesh cloth can effectively disperse stress and prevent wall cracking with its high-strength fiberglass material. In the French exterior wall insulation project, the crack incidence rate of the wall using mesh cloth was reduced by more than 80% compared with that of the wall without mesh cloth, which greatly improved the beauty and durability of the building.

(II) Enhanced protection ability

After the mesh cloth is compounded with cement-based, resin and other materials, it can significantly improve the tensile and shear strength of the material. In the restoration project of historical buildings in Germany, the walls reinforced with mesh cloth not only restored their original appearance, but also enhanced their earthquake resistance, giving the ancient buildings a new lease of life.

(III) Environmental protection and energy saving

Glass fiber mesh cloth is an inorganic material that does not release harmful gases and meets Europe's strict environmental protection standards. At the same time, when used in building insulation systems, it can effectively reduce heat transfer, help buildings achieve energy-saving goals, and conform to Europe's "carbon neutrality" development trend.

2. Reasons for widespread application

(I) Policy promotion

The EU has introduced a series of building energy conservation and environmental protection regulations, such as the "Building Energy Efficiency Directive", which requires that new and renovated buildings must use high-efficiency insulation materials and technologies. As a key material for exterior wall insulation systems, glass fiber mesh cloth has benefited from policy support and market demand has continued to grow.

(II) Mature technology

After decades of development, Europe has become very mature in the production process and application technology of glass fiber mesh cloth. Standardized production processes and perfect construction specifications ensure product quality and application effects, and have won the trust of the construction industry.

(III) Cost-effectiveness

Compared with other high-performance reinforcement materials, fiberglass mesh has a higher cost-effectiveness. It has a long service life and low maintenance cost. In the long run, it can save a lot of money for construction projects, which is also an important reason why it is so popular.

III. Expected development

(I) The market scale continues to expand

With the advancement of the European "green building" movement, it is expected that the market scale of fiberglass mesh in the construction field will grow at an average annual rate of 8% in the next five years, especially in the fields of existing building renovation and passive house construction. The demand potential is huge.

(II) Acceleration of technological innovation

In order to meet higher building performance requirements, companies will increase R&D investment and develop new fiberglass mesh products with higher strength, lighter weight and easier construction. At the same time, cutting-edge technologies such as nanotechnology and smart materials are also expected to be applied.

(III) Expansion of application fields

In addition to the construction field, fiberglass mesh will have more application opportunities in the fields of automobile lightweighting and wind turbine blade manufacturing, further opening up market space.

4. Common specifications

(I) Width

The common width is 1 meter, and there are also 1.2 meters specifications, which are convenient for construction operations, reduce splicing, and improve construction efficiency.

(II) Weight

Varies from 80 g/m2 to 160 g/m2. 80-100 g/m2 is suitable for general wall plastering reinforcement; 120-160 g/m2 is mostly used for exterior wall insulation systems and high-strength reinforcement requirements.

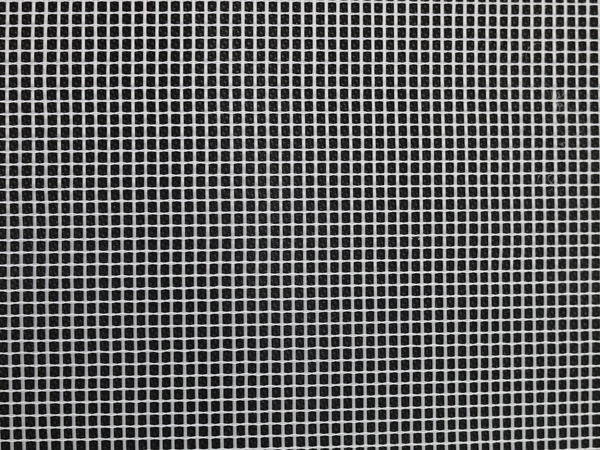

(III) Mesh size

The commonly used mesh sizes are 4×4 mm and 5×5 mm. Reasonable mesh design can not only ensure good bonding with the substrate, but also effectively disperse stress.

5. Common packaging methods

(I) Plastic film packaging

The use of transparent or colored plastic film to wrap the mesh cloth can effectively prevent moisture and dust, and protect the product from damage during transportation and storage. Product specifications, brand logos and other information are usually printed on the outside of the package.

(II) Paper core roll packaging

Wrap the mesh cloth around the paper core and seal the two ends with plastic or paper covers to prevent the edges from loosening. This packaging method is easy to carry and use, and is suitable for bulk cargo transportation.

(III) Woven bag packaging

For large-sized and heavy mesh cloth, woven bags are often used for packaging. They have the characteristics of high strength and wear resistance, and can meet the storage needs of long-distance transportation and harsh environments.

With its unique advantages, glass fiber mesh cloth has gained a firm foothold in the European construction market and has shown strong development momentum. In the future, with the advancement of technology and the expansion of the market, it will surely shine in more fields and contribute more to the development of construction and industry.

Share