fiber chopped strand mat

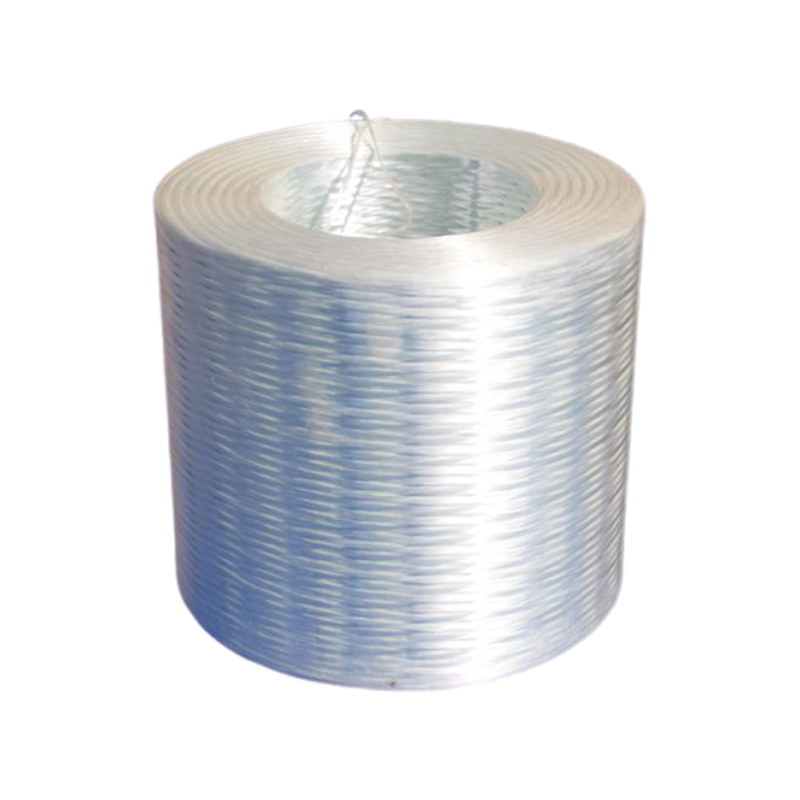

Fiberglass roving, as the basic raw material, needs to be cut according to the specifications of the required chopped strand mat first. Usually, specialized fiber cutting equipment will be used to cut the continuous fiberglass roving into short fibers of a specified length. The length generally ranges from a few millimeters to dozens of millimeters. For example, the common chopped lengths are from 6 to 50 mm, and such short fibers are more convenient for subsequent processing and forming.