Products center

Contact

Add: Room 307, Merchants Building, Funing District,Qinhuangdao City, Hebei Province China

Tel:8615233019126

Email:sales@tymaterial.com

Fiberglass Yarn

Help complete your project with CE-compliant, versatile and customizable Fiberglass Yarn

30% OFF

Fiberglass Yarn

Fiberglass Yarn

Product Description

Product Features

|

Specification

Fiber diameter

The fiber diameter of fiberglass yarn usually ranges from 3 to 20 micrometers. For example, in some application scenarios with higher requirements for flexibility, such as manufacturing insulating materials for fine electronic components, fiberglass yarn with a diameter of 3 to 5 micrometers may be used, which can make the final products thinner, lighter and more precise. While in applications where higher strength is required, like building reinforcement materials, the diameter may reach 10 to 20 micrometers.

Strand number

The strand number can vary from a single strand to multiple strands. Single-strand fiberglass yarn is relatively thin and suitable for occasions with high requirements for fineness. Multi-strand yarn is formed by twisting two or more single-strand yarns together. Common ones include 2-strand, 3-strand, 6-strand and 12-strand, etc. For instance, when making ropes or knitted products that need higher strength, multi-strand yarn will be used. The 12-strand fiberglass yarn can provide sufficient strength for ship mooring ropes.

Twist level

Twist level refers to the number of twists of the yarn per unit length. The magnitude of the twist level will affect the strength, flexibility and other properties of the yarn. Generally, the twist level ranges from 10 to 100 twists per meter. Yarn with a lower twist level (such as 10 to 30 twists per meter) is relatively soft and suitable for weaving fabrics that require a certain degree of flexibility, such as glass fiber cloth used for clothing linings. While yarn with a higher twist level (such as 60 to 100 twists per meter) has higher strength and is more suitable for manufacturing products that need to withstand greater tensile forces, like structural parts in glass fiber reinforced plastics.

Linear density

Linear density is an indicator for measuring the thickness of yarn, and its unit is tex. It represents the weight in grams of 1000 meters of yarn at the official moisture regain rate. The linear density of fiberglass yarn can range from several tex to several hundred tex. For example, the yarn used for insulating fine electronic circuit boards may only have several tex, while the yarn used for large-scale building reinforcement materials may reach several hundred tex.

Company Profile

Qinhuangdao TongYu Building Material Co.,LTD

Qinhuangdao Tongyu Building Material Co., Ltd. Is dealing in fiberglass mesh,fiberglass self adhesive tape,other building material and thermal insulation materials, plastic products, packaging materials.Our company has been committed to energy-saving environmental protection projects; always adhere to the "integrity and win-win" for the purpose of the enterprise, "technology and services" for the Founding of the community spirit and the formation of a complete service system.

Our company has established good and stable business relationship with many customers all over the world, seeking development in the competition, in the face of challenges and believe that our company will provide you with the best and most advanced products, I believe our company will provide you with the most advanced technology and perfect after-sales service. Our company that with hardworking and sincere is willing to go hand in hand with you, create brilliant!

Why Choose Us

Quality Assurance:Strict quality testing, precise control specific-actions final quality control before shipment.CE certification.

Professional Advantage:Over 20 years of professional production and export experience.Working with many clients for different countries and keep the long-term cooperation.

Team Advantage:Company scale, sales team specialization, professional technical team,Focus on customer service. The team is mature and experienced in production and export.

OEM Service:Products can be customized according to customer requirements. Meet the different needs of customers.

After-Sale Advantage:Short delivery period, transportation quality assurance, long time guarantee period.

Quality Assurance

Professional Advantage

Team Advantage

OEM Service

24/7After-sale Service

Packing & Shipping

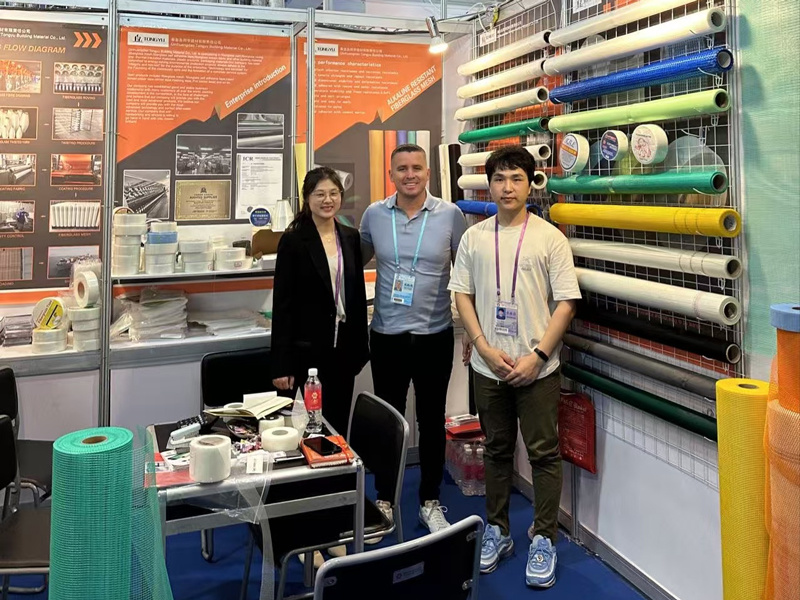

Exhibition

Tongyu Excellent Performance At The Exhibition. To build global connections and explore the largest market.

Contact Info

Take advantage of all these benefits by placing your order today!

· Free samples for testing your projects!

· A catalog of various styles!

· Product customization plan!

· Problem solution!

Room 307, Merchants Building, Funing District,Qinhuangdao City, Hebei Province China

Phone/WhatsApp:

E-mail:

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!